To do this I looked at a single zone on the upstairs heat pump that controls the temperature for the two guest bedrooms. During this past summer when the guest bedrooms were not in use the thermostat was set to 80 degrees. When we did have a guest using one of the bedrooms, the thermostat was set to 76. The rest of the house is set to 76.

I then went through the data for the summer and collected information on 6 days where the outside temperature and attic temperature were roughly the same. On half of those days the guest bedrooms were not occupied and the thermostat was set at 80. On the other half the bedrooms were occupied and the thermostat was lowered to 76.

Below are the graphs for the attic and outside temperatures during those 6 days. The data graphed in red is the attic temperatures, blue is the outside temperature.

|

| Daily temps with guest rooms unoccupied. |

|

| Daily temps with guest rooms occupied. |

The data for the guest bedroom zone was then graphed (shown below) when the thermostat was set to 80 degrees. Average run time for the three days was 123 minutes per day. Note that the zone typically didn't call for cooling until late in the day when the outside and attic temperatures were near their maximum.

|

| Thermostat set to 80 |

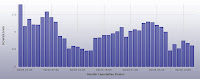

The data for the guest bedroom zone was then graphed (shown below) for days when the thermostat was set to 76. Note that the zone calls for cooling throughout the entire day and that by the time the hottest part of the day arrived, the zone had already been calling for cooling for over 200 minutes. Average run time for the 3 days was 560 minutes per day.

|

| Thermostat set to 76 |

What did I learn from this? There was a 78% reduction in the time that the zone is calling for cooling when the thermostat was set to 80 instead of 76. Installing a programmable thermostat and actually programming it (instead of just pushing the "hold" button), can have a dramatic affect on the amount of time your hvac system runs.